Production process

Step-by-step fulfilment of an order

The production process begins with roundwood.

Such prepared batch of logs are debarked and sawn with the utmost attention to the accuracy of dimensions and efficient use of the precious raw material, which constitutes a renewable natural resource of our region.

Following the sawing, wet sawn wood is quality sorted and stacked on sticks. Such prepared wood packages are placed in drying kilns and dried in controlled conditions for 4–7 days.

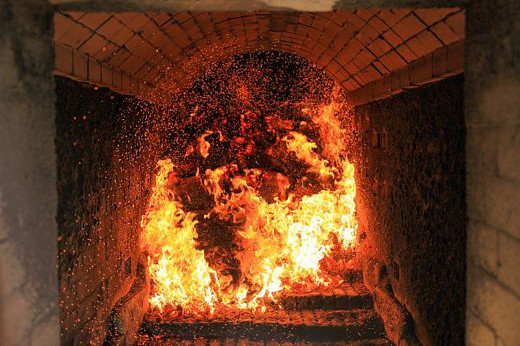

The process of drying requires huge quantities of heat, which is generated using only ecological renewable sources (wet biomass) in a modern heating installation.

After drying, sawn wood is removed from sticks, sorted into grades and lengths and stacked in packages ready for shipment. Upon request, sawn wood is planed and cut to length.

The whole process results in the generation of by-products – bark, sawdust and paper chips. However, nothing goes to waste: we sell bark to garden centers, burn sawdust for the purpose of wood drying or sell it to producers of pellet and distribute fractioned paper chips to paper mills.